There are several boat designs that can be expected as the move away from fossil fuels continues. These include:

- Solar-powered boats: Solar power is a renewable energy source that can be used to power boats. Jeroen Droogsma, head of design studies at Vripack, has been working with solar-powered boats for 10 years see 1.

- Hydrogen fuel cell technology: The Netherlands and Norway are leaning towards hydrogen fuel cell technology for marine application1. Hydrogen can be supplied as a pure gas held in tanks or manufactured on site through the electrolysis of water see 1.

- Methanol and other fossil-fuel alternatives: Some pilot projects are using fossil-fuel-based methanol to power ships, and some companies have signed deals to secure enough green methanol to start using it as a fuel see 2.

- Wind-assisted propulsion: Wind assisted propulsion is the practice of using sails or a type of wind capture device see 3.

- Fuel cell propulsion: Fuel cells convert fuel more efficiently than traditional combustion engines, reducing pollution and greenhouse gas emissions see 3.

- Non-fossil paraffinic fuels and alcoholic fuels: Feadship has developed a fully integrated system that is able to store both non-fossil paraffinic fuels and alcoholic fuels at full capacity see 4.

- Hull form optimization: Hull form optimization is a technique used to reduce drag and improve fuel efficiency see 5.

In summary, boat designs that can be expected given the move away from fossil fuels include solar-powered boats, hydrogen fuel cell technology, methanol and other fossil-fuel alternatives, wind-assisted propulsion, fuel cell propulsion, non-fossil paraffinic fuels and alcoholic fuels, and hull form optimization.

There are also attractive retrofitting possibilities.

Electronic engine and transmission controls (EEC) can improve the fuel economy of a dual screw boat by optimizing the engine and transmission performance. As with most boats, the fuel efficiency depends on several factors such as the boat’s size, weight, and engine specifications. According to1, electronic controls can increase propulsion’s efficiency by 3-8% for single-screw vessels

Driving a given yacht at a given speed under the same load and sea conditions depends on the amount of thrust delivered by the propeller or propellers. Hence, different propellers will be mounted for fuel efficiency than when the operator wants maximum speed.

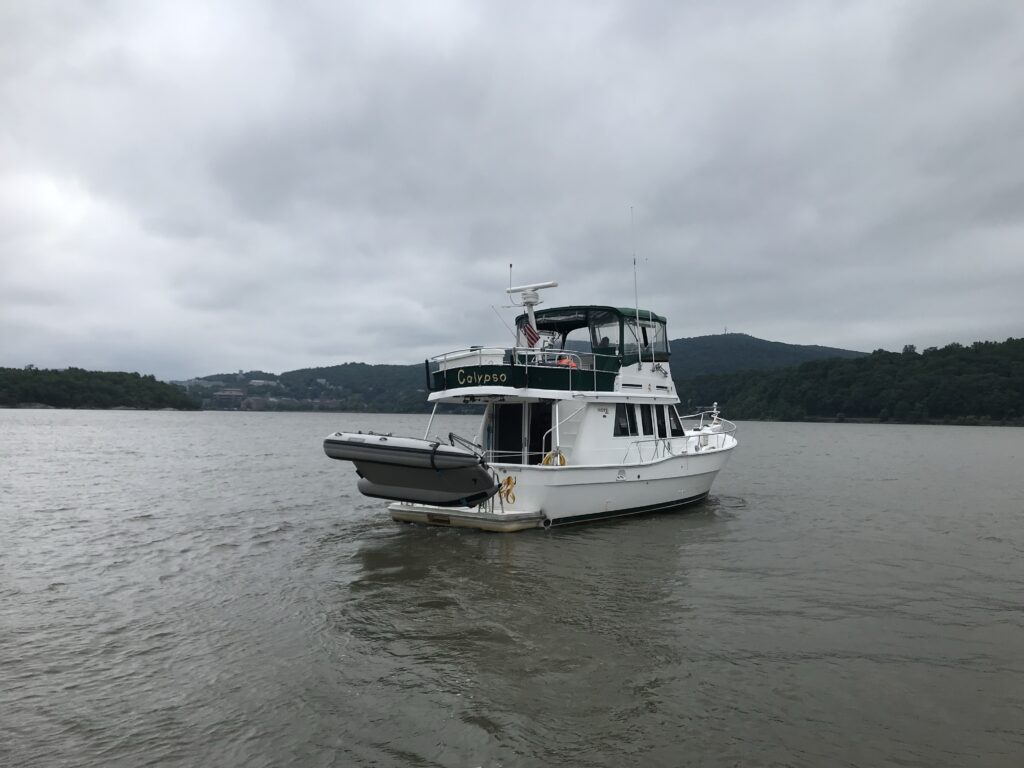

When family members decided to complete America’s Great Loop, they selected a single screw Mainship trawler after consulting with loop experts knowledgeable of the most fuel-efficient propulsion system for a boat running at displacement speeds. A single-engine trawler is more economical than a twin-screw, semi-displacement boat according to.. https://www.passagemaker.com/technical/feel-the-burn. However, this depends on the boat’s hull shape, weight distribution and cruising area conditions.

While historically, single-engine installations in yachts have been thought to be more economical than twin-engine setups, this is mostly a myth. The number of engines and screws have little to do with overall expenditures. The speed, load, sea conditions and amount of thrust delivered by the propeller or propellers is what is important. In general, twin screw configurations are used for maneuverability and redundancy rather than fuel efficiency2.

However, 2 also suggests that twin screw configurations can be more fuel-efficient than single screw configurations, with an estimated 15% difference in overall fuel efficiency. Fuel consumption is measured in gallons per hour, and it can be estimated using the formula GPH = (specific fuel consumption x HP)/Fuel Specific Weight. The specific fuel consumption and fuel specific weight depend on the type of fuel used. Gasoline weighs about 6.1 pounds per gallon, while diesel fuel weighs about 7.2 pounds per gallon. GPH is used rather than MPG because currents and wind impact the numbers of miles traveled but not hours.

To optimize fuel efficiency during a long-distance boat trip, there are several tips that can be followed. According to1, one of the major factors that affects the overall performance of a boat-engine combination and its fuel consumption is the propeller. Matching the correct propeller to the boat and cruising area can improve fuel economy. Additionally, it is important to distribute weight evenly along the boat’s centerline and consider the boat’s fore-and-aft balance. This includes positioning passengers, gear, and fuel evenly and adjusting the boat’s trim using trim tabs or the motor’s tilt and trim function when necessary2.

Furthermore, 3 suggests that installing a fuel flow meter can help monitor fuel efficiency in real-time. It is also important to ensure that the engine is well-maintained and that the oil level is neither too little nor too much, as this can harm the engine, affect overall performance, and reduce fuel efficiency.

Finally, 4 recommends incrementally adding up tactics that improve fuel economy, such as reducing speed, avoiding idling, and planning the route to take advantage of favorable currents and winds. It is also important to calculate the boat’s fuel consumption rate using the appropriate formula5 and to develop a boat fuel consumption chart to monitor fuel usage during the trip.

My family and I spent a decade with twin screw 60 foot and larger wooden and steel motor vessels. This was before bow and stern thrusters. Owing to always increasing fuel costs, we transitioned to smaller displacement hulled sailboats and the Macgregor 26x power sailor. But the desirability of bow and stern thrusters was never clear to me until 2023.

With both bow and stern thrusters, the maneuverability of a dual screw vessel can be obtained. We learned that putting one engine in reverse and the second in forward was not necessary to make tight turns for docking MV Seahome. We could use thrusters instead. Best of all, with both thrusters, Seahome could parallel park in between boats already tied to the fuel dock. What’s more, there was no awkward dismounting the boat to tie off lines or need to request assistance from shore to take lines. We didn’t need a boat hook to pick up lines made ready for us. The two thrusters could be put in hold mode, thereby holding the boat against the dock until we stepped off the swim platform to affix our deck lines.

Hence, while twin screw configurations are generally believed best for maneuverability, that advantage over single screw design is lost when bow and stern thrusters are available. As discussed above, the fuel efficiency of a single screw can be met (contrary to general perceptions) with twin screws. Nonetheless, the common perception is that a single screw is a better design. Now let’s consider redundancy.

With the renovation of Western Flyer, we had a number of choices of what to use for a propulsion system. We really wanted to do a pure electric vessel, but then reality intruded. This is a rapidly changing technology, but prices are still very high. We estimated that it would cost at least $1.2M to install the necessary batteries and motors, and whatever we came up with would likely be obsolete within 5 or 6 years. That’s a cost that we just couldn’t afford.

It would also come with a number of operational limitations. While it would be very green in a state such as California with its relatively low-carbon electrical grid, that would not be the case in Mexico, where we expect to spend up to a quarter of our time. There, the grid is largely coal and oil-fired, leading to total emissions that would actually be higher than a modern tier-four diesel!

So, we chose to do the next best thing: a diesel-electric hybrid. This is a system that is largely diesel-powered but can switch to electric mode for relatively brief periods of time. Besides being cleaner, a diesel-electric has several other advantages. The Western Flyer will have to hold research stations for long periods of time, which requires a slow-turning motor that reverses a lot, both of which diesels hate doing. For a long-haul, cargo-carrying ship that’s not a problem — they just put the thing in gear in Yokohama and don’t take it back out until they reach Oakland — but, for us, who might be reversing hundreds of times in a day, it would be inefficient and mechanically troublesome. With a hybrid system, we can just switch to electric mode, allowing speeds from zero to full max 1850 RPM, in forward and reverse, with just a single control and no clutch engaging and disengaging.

Running a hybrid also opens up some very interesting research possibilities. When in electric mode, the boat, with its wooden hull and electric motor, will be extraordinarily quiet and less intrusive in near-shore environments. We wonder what scientists might be missing when approaching an area with a thumping diesel and a loud exhaust stack. We will be able to sit quietly in a patch of water for long periods of time, watching and observing.

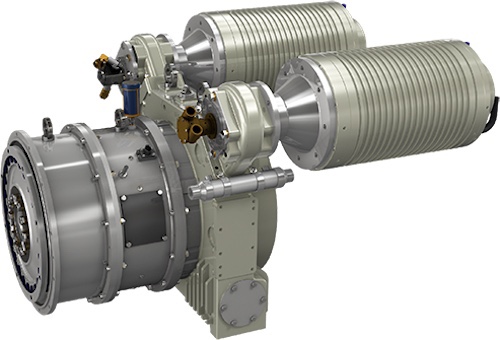

The system we chose uses a traditional John Deere 6135 marine diesel (425 HP or 320 kW), mated to a Transfluid HM3350, manufactured in Italy. Looking a bit like the Starship Enterprise, the unit sits between the diesel and the gearbox. It has two 50 kW motors (the “warp drives”), which are engaged through a pinion gear and clutching mechanism when in electric mode.

https://www.westernflyer.org/

It should be apparent from the above quote that the single-engine single-screw MV Western Flyer has engine redundancy like a twin-engine twin-screwed vessel. It gains that advantage by the electric motor from Italy.

I view the Wester Flyer as Yacht Design’s Future. It is not just its retrofit to a hybrid but also the boat’s construction in carbon neutral wood. The days of low cost new plastic boat hulls are pretty much over for the next 30 years because of the cost of fossil extractions, their link to global warming and the backlash that can be expected from knowledgeable young boat buying consumers.

Architects note that the most green structure is the one already built and that applies to boats as well as land structures. So conservation of plastic hulls – especially the efficient ones – and upgrades in propulsion will be the most common design activity.

New hull construction should be from something other than fossil extractions. Wood, Aluminum and Steel are alternatives – not fiberglass – unless it is made from carbon neutral not-fossil ingredients. As explained below, those carbon neutral ingredients are needed for refining renewable fuel.

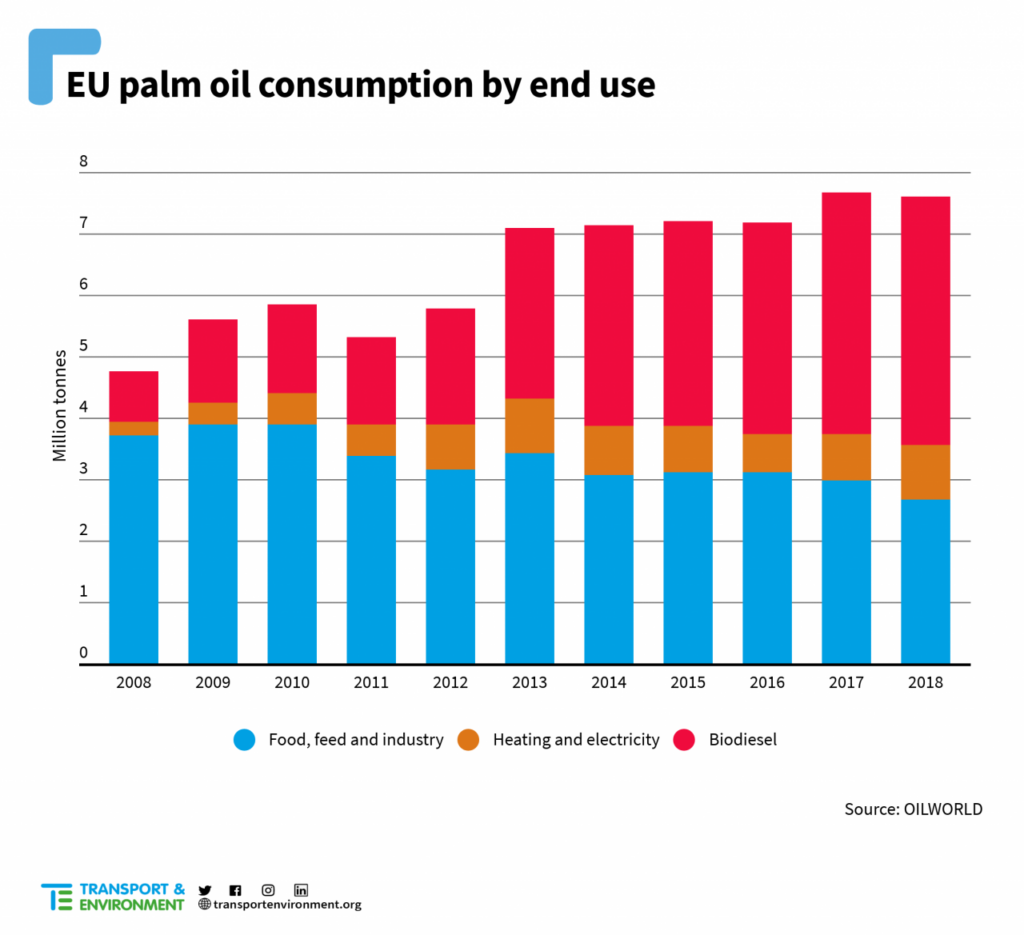

Drivers in Europe fill up their diesel cars with palm oil biodiesel. In 2018, 65% of all the palm oil imported into the EU was used for energy. More than half (53%) of all EU palm imports were used to make biodiesel for cars and trucks and 12% was used to generate electricity and heating. Palm oil used for biodiesel grew again in 2018 – by 3% – while the use of palm oil to make food and animal feed dropped significantly, by 11%.

In the USA, laws protecting fossil extractions and non palm oil biofuel do not exist and refineries are synthesizing palm oil into chemically identical to fossil diesel fuel. The United States has a mandatory biofuel program that requires the use of renewable fuels, including palm oil, in transportation. In tropical areas, forest oil palm farms are replacing foodstock crops used for biofuel like soy and sugar cain. It takes one quarter of the land to produce the same amount of fuel. The trees produce 18 months after planting and can be managed into rainforests and wilded. The cure for global warming is palm oil production because trees absorb CO2 and fossil extractions can be halted in years rather than decades. It can be less expensive than fossil based extractions. And the future for boat designs involves using refined palm oil to replace fossil fuels while going electric as well as using wind. In the near term, it is renewable palm oil based fuels driving yacht designs because current engines do not need replacement or modification and fuel consumption can be lessened with electronics and changes in operation.

See also Fuel for thought: How alternative energy is powering the future of superyachts.

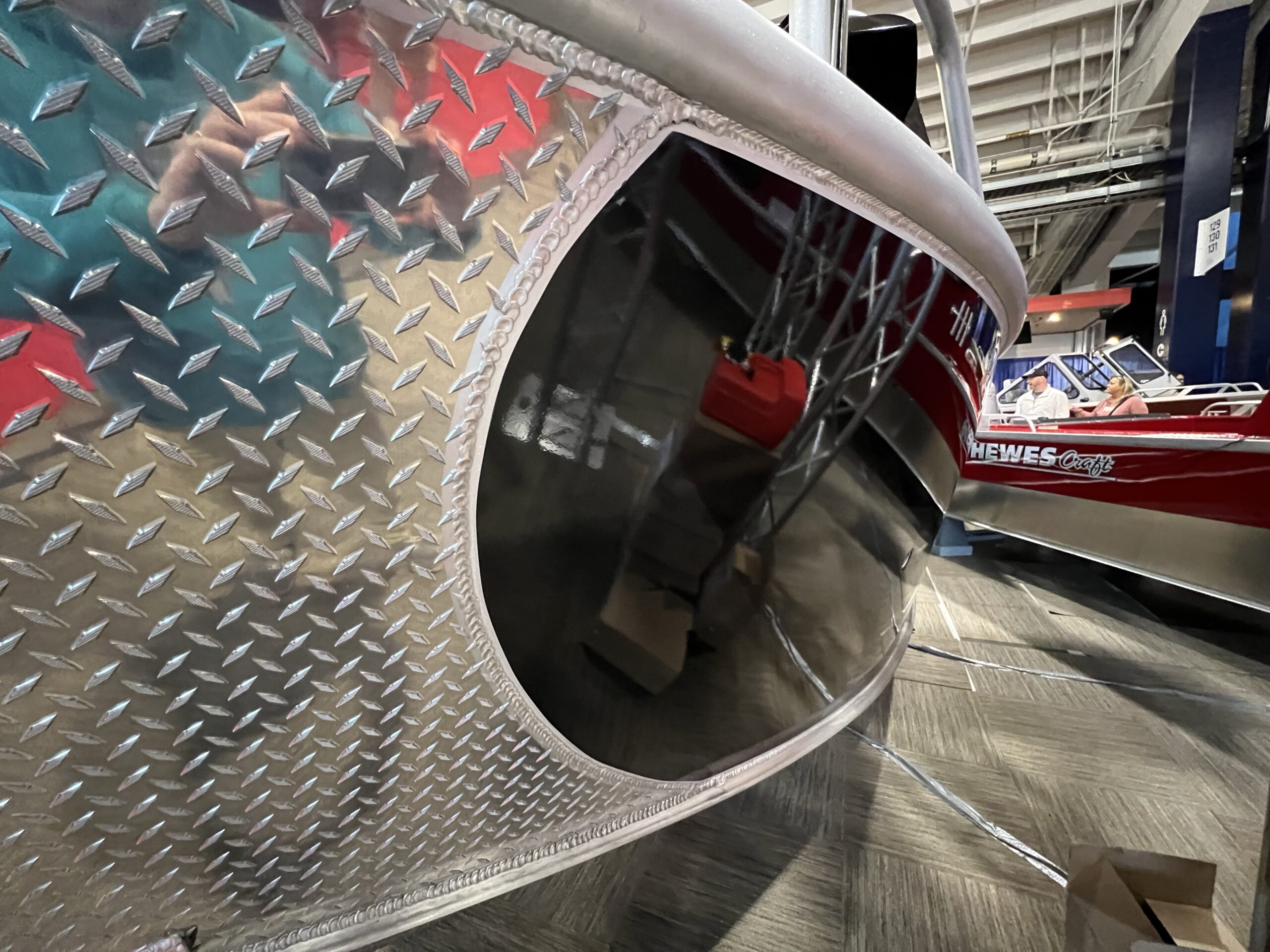

Several outboard models now integrate hybrid or electric options, with some being displayed at the 2025 Seattle Boat Show. Here are the key highlights:

- Pure Watercraft Electric Outboards:

- Partnered with Highfield Boats to showcase two new electric boat packages.

- Models include the Pure Watercraft RIB Classic 360 and Highfield 12’6″ Deluxe 360.

- The RIB Classic 360 achieves a top speed of 28 mph with a range of 86 NM at 5 mph.

- These models are being displayed at the 2025 Seattle Boat Show.

- Yamaha HARMO:

- While not explicitly mentioned in the search results, this 9.9 hp equivalent electric outboard system is likely to be showcased, given its recent launch and popularity.

- Ocean Sport Boats:

- Introducing new models at the 2025 Seattle Boat Show, including the Ocean Sport 27 and Ocean Sport 36.

- While not specified as hybrid or electric, these models offer “a wide range of outboard power options,” which may include electric or hybrid systems.

- Lifeproof Boats:

- Displaying their newest 18FT Aluminum Hulled RIB with a patent-pending hybrid collar system.

- Also showcasing a 25FT Full Cabin model with both single and twin outboard configurations.

- Nautique Electric Wakeboard Boat:

- While this is not an outboard model, it’s worth noting that Nautique displayed a 100% electric prototype of their 210 model at a previous Seattle Boat Show, indicating ongoing development in the electric boat sector.

YAMAHA’S HARMO® ELECTRIC OUTBOARD SYSTEM MAKES U.S. DEBUT AT IBEX

POSTED 9/28/2021

The 2025 Seattle Boat Show features a dedicated section for electric propulsion and hybrid-electric systems, suggesting a growing presence of these technologies in the marine industry. However this technology is expensive.

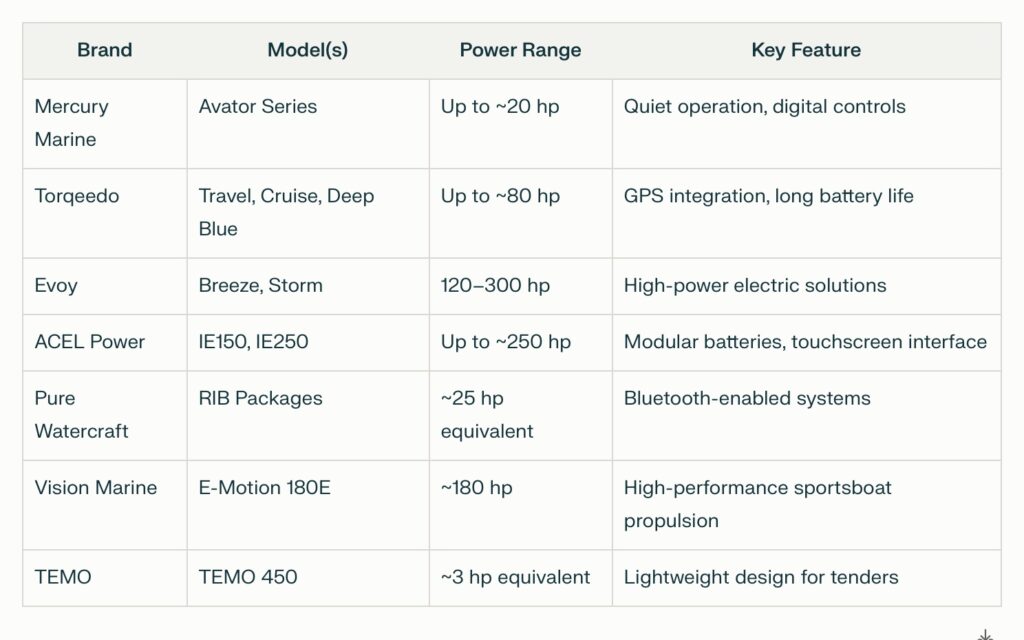

At the forefront of hybrid and electric outboards are brands like Mercury Marine (Avator), Torqeedo, Evoy, ACEL Power, and Pure Watercraft—many of which are prominently featured at the 2025 Seattle Boat Show. These brands are driving innovation in sustainable marine propulsion by offering models that cater to both recreational boaters and high-performance enthusiasts.

Concern for the environment impacts boat design beyond just propulsion. For decades there has been concern regarding waste disposal.

Here are the regulations for sewage discharge from recreational boaters in Washington State results123456:

- Boaters are not allowed to discharge sewage, treated or untreated, into Puget Sound1235. Puget Sound is about 95 miles long and 1 to 5 miles wide, with its northern boundary at Admiralty Inlet and ending in the south at the city of Olympia4.

- Puget Sound is now a no-discharge zone for vessel sewage3.

- The vessel sewage rule is effective as of May 10, 2018, for all recreational boats, and was adopted on April 9, 20183.

- Most recreational boats already have holding tanks that can store sewage until it can be safely disposed of at an onshore or mobile pumpout facility, or discharged in the open ocean beyond three miles from shore4.

- Federal law allows vessels to dump raw sewage only in waters more than three miles from shore5.

- Discharge of untreated sewage is only permitted beyond the three nautical mile ocean limit6.

In summary, recreational boaters in Washington State are not allowed to discharge sewage, treated or untreated, into Puget Sound, which is now a no-discharge zone for vessel sewage. Most recreational boats already have holding tanks that can store sewage until it can be safely disposed of at an onshore or mobile pumpout facility, or discharged in the open ocean beyond three miles from shore. Federal law allows vessels to dump raw sewage only in waters more than three miles from shore, and discharge of untreated sewage is only permitted beyond the three nautical mile ocean limit.

The above regulations are routinely ignored by all but the most environmentally conscious USA boaters and charter operators. Puget Sound is an inlet of the Pacific Ocean, located along the northwestern coast of the US state of Washington25.

Some believe it is OK to dump treated sewage into The Strait of Juan de Fuca which flushes water from Puget Sound into the Pacific Ocean twice per day. See below:

The current state of the marine environment in the Strait of Juan de Fuca is a mix of positive and negative aspects. Here are some relevant points results123456:

Positive aspects:

- The Strait of Juan de Fuca supports significant populations of groundfish, clams, shrimp, sea urchins, and Dungeness crab, as well as other fisheries resources5.

- The cleanest water Victoria has ever put into the ocean is being discharged into the Strait of Juan de Fuca6.

Negative aspects:

- The Strait of Juan de Fuca has been polluted by untreated sewage from Victoria, British Columbia, for over a century36.

- Sewage dumped into the Juan de Fuca Strait from places like the Capital Regional District accounted for billions of liters of untreated sewage13.

- Decades of dumping raw sewage have killed Victoria’s ocean floor1.

- The marine environment and biota of the Strait of Juan de Fuca, Strait of Georgia, and Puget Sound have been impacted by pollution3.

- The Strait of Juan de Fuca sees over 8,000 transits of deep-draft container ships, cargo4.

In summary, the marine environment in the Strait of Juan de Fuca is impacted by pollution, but it also supports significant populations of fisheries resources. The recent sewage treatment plant in Victoria, British Columbia (2020) has ended the practice of releasing untreated sewage directly into the ocean near Victoria, which is a positive development for the marine environment in the Strait of Juan de Fuca. Boaters are unaware that Victoria no longer dumps raw sewage into the Strait.

The rules for Canadian Boaters are the same in Puget Sound as for USA boaters.

Here are the regulations for sewage discharge from recreational boaters in British Columbia based on the search results123456:

- Lax regulations allow the discharge of raw sewage across much of the BC coast1.

- Currently, Canadian regulations only prohibit the dumping of sewage within three miles of the shoreline2.

- A person must not discharge domestic sewage or waste from a trailer, camper, transportable housing unit, boat, or houseboat onto land, into any reservoir, or…3.

- Transport Canada regulations prohibit the discharge of raw sewage directly into the water4.

- Boaters are not allowed to discharge sewage, treated or untreated, into Puget Sound56.

- The vessel sewage rule is effective as of May 10, 2018, for all recreational boats, and was adopted on April 9, 20186.

- Most Canadian recreational boats already have holding tanks that can store sewage until it can be safely disposed of at an onshore or mobile pumpout facility, or discharged in the open ocean beyond three miles from shore6.

- Graywater discharges are not affected by the vessel sewage rule6.

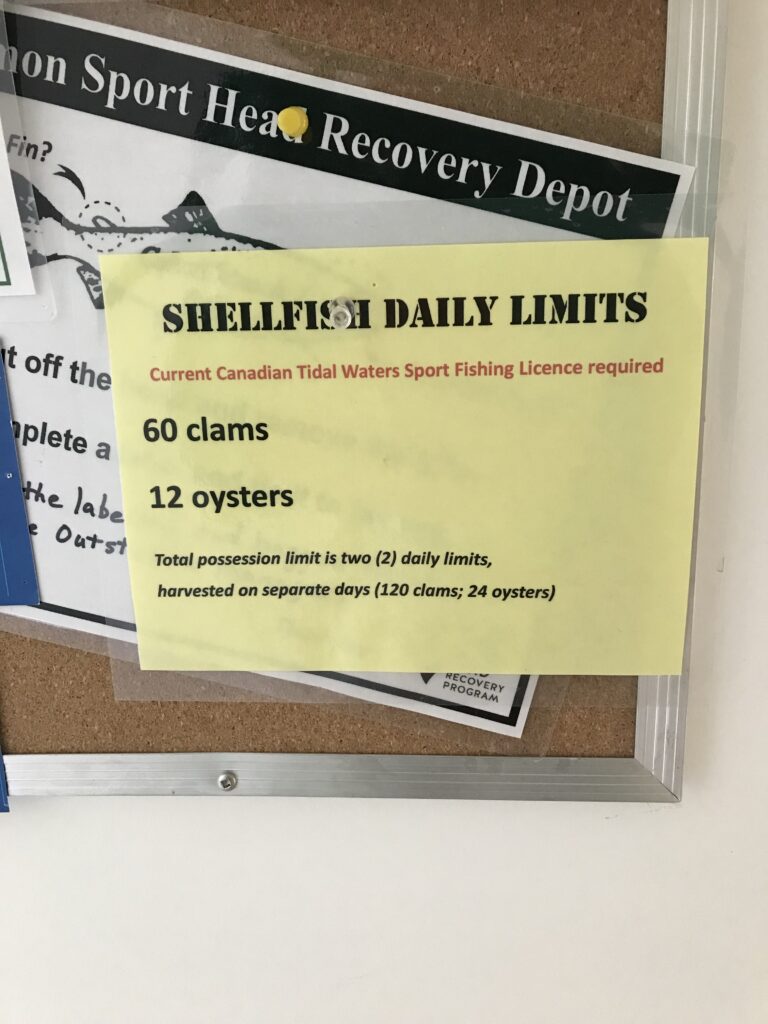

- Even small amounts of sewage discharges over or near shellfish beds can cause enough pollution to require harvest closures6.

In summary, the regulations for sewage discharge from recreational boaters in British Columbia are relatively lax, and Canadian regulations only prohibit the dumping of sewage within three miles of the shoreline. However, Transport Canada regulations prohibit the discharge of raw sewage directly into the water. Boaters are not allowed to discharge sewage, treated or untreated, into Puget Sound, which is now a no-discharge zone for vessel sewage. Most recreational boats already have holding tanks that can store sewage until it can be safely disposed of at an onshore or mobile pumpout facility, or discharged in the open ocean beyond three miles from shore. Graywater discharges are not affected by the vessel sewage rule, but even small amounts of sewage discharges over or near shellfish beds can cause enough pollution to require harvest closures.

Owing to the above, the yacht design future will will involve addressing waste in a more significant way. The designs for boats that are chartered will be the first.

Here are the relevant points from the search results123456 regarding the requirement for boat charter operators to pump out vessels after renting:

- All boats and vessels are required to store their sewage until it can be safely disposed of at an onshore or mobile pumpout facility, or hold it until it can be discharged in the open ocean beyond three miles from shore4.

- Previously, federal regulations allowed treated sewage to be discharged anywhere in Puget Sound, and untreated sewage could be discharged as long as the boat was more than three miles from shore. With the no-discharge zone now in effect, no boat of any kind or size can discharge sewage wastewater anywhere within the zone4.

- Boat owners or rig operators face stern boat sewage regulations and steep repercussions surrounding the use of their marine sanitation device6.

- To help keep shared water safe, it’s against federal law to discharge any sewage that you haven’t safely treated. This applies to any vessel that’s in U.S. navigable waters6.

- Boat charter operators are required to follow all of the main boat sewage regulations from previous years6.

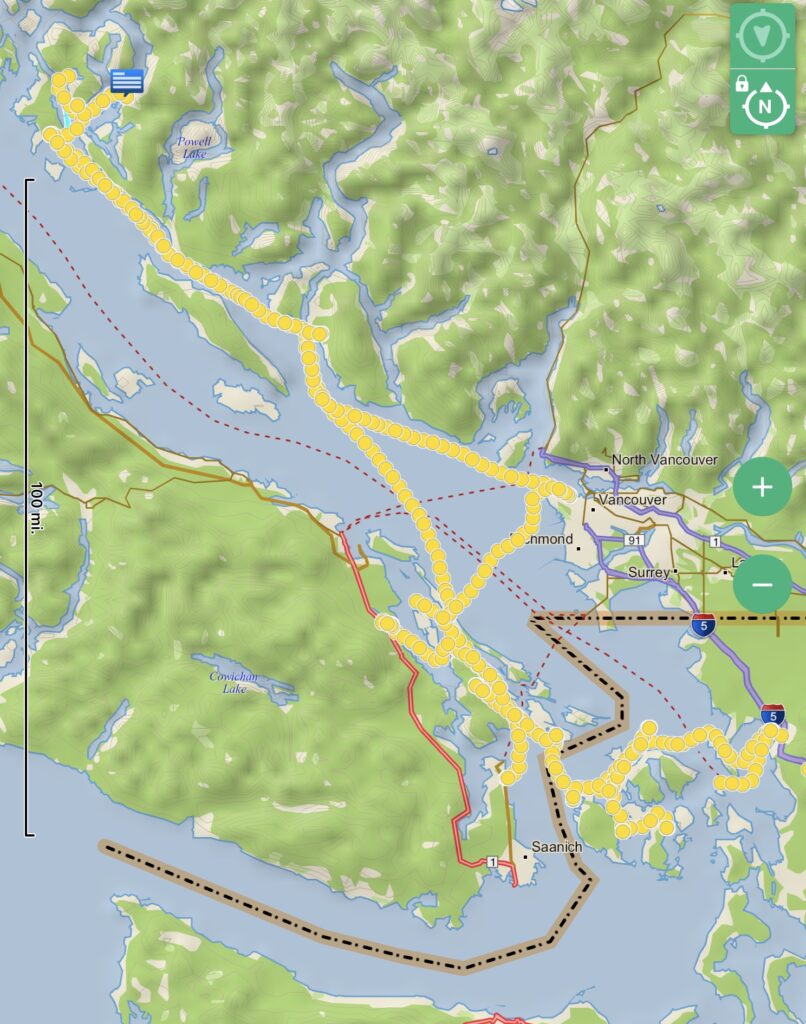

Besides going 3 miles into the Pacific Ocean, which is unusual for a recreational boater, there are three methods of emptying a boat’s holding tank in my cruising area, the Salish Sea. Traveling at least three miles offshore in Canada and emptying treated sewage there is still legal. You can pump out the tank at a dock providing that service or call for a pump out service boat, or you can let the legally liable charter service do the pumping. The latter option makes vessels with large holding tanks desirable. Boats will be designed and modified with that in mind.

In summary, USA boat charter operators are required to store sewage until it can be safely disposed of at an onshore or mobile pumpout facility, or hold it until it can be discharged in the open ocean beyond three miles from shore. Federal law prohibits the discharge of any sewage that has not been safely treated, and boat charter operators are required to follow all of the main boat sewage regulations from previous years.

Recreational boaters may ignore requirements to use pump out stations because of the nature of the task. However, there are several ways that boaters are encouraged to use pump out stations.

- Information and education programs that encourage boaters to use pump outs1.

- Easy access to marina pump out stations24.

- Guidelines that encourage everyone to use the shoreside facilities before casting off3.

- Portable pump-out stations like the Todd Waste Caddy that can be brought to the boat4.

- Grant programs that help fund the construction, renovation, and maintenance of pump out and dump stations to service pleasure boats5.

These initiatives aim to make the pump out process more convenient and accessible for boaters, and to raise awareness about the importance of using pump out stations to keep the water clean.

The usual method of pumping out a marine holding tank is similar to that used for a recreational vehicle. Here are the steps to pump out a boat’s holding tank123:

- Remove the cap from the boat’s deck waste fitting.

- Insert the pumpout hose nozzle into the deck fitting.

- Turn on the pump. If there is a hose valve, open it to start the suction.

- When no waste is seen in the sight glass, close the hose valve and remove the nozzle from the deck fitting.

- Put the nozzle (with the open valve) in a bucket of water for 15 seconds to rinse the hose. If desired, rinse the boat’s holding tank with water and pump it dry.

- Close the valve, put away the hose, and replace the deck fitting cap.

There are also ship board pumps that can be involved in emptying a boat’s holding tank, these are macerating and bellows pumps.

A macerating pump is a type of pump that grinds up solid waste and toilet paper into small pieces, making it easier to pump out of the holding tank. It is commonly used in marine applications to pump out holding tanks. Here are some relevant information about macerating pumps123:

- Macerator pumps are the key to a number of important chores on a boat.

- They are used to pump out holding tanks and can be used in non-gravity feed situations.

- They can be self-priming and have run-dry protection.

- They are available in different sizes and capacities.

- They can be mounted on the boat or portable.

Therefore, a macerating pump can be used at a marine pump out station to pump out holding tanks.

Using a macerating pump for marine pump out stations has several benefits. Here are some of them12:

- Macerating pumps grind up solid waste and toilet paper into small pieces, making it easier to pump out of the holding tank.

- They can be used in non-gravity feed situations, which means they can pump waste uphill or over a long distance.

- They can be self-priming and have run-dry protection, which means they can be turned on and off easily and won’t get damaged if they run without liquid going through them.

- They can be used to empty fish boxes as well as holding tanks.

- They can prevent clogs and blockages in the pump out station’s hoses and pipes.

Overall, using a macerating pump can make the pump out process more efficient and effective, especially in situations where gravity feed is not possible.

Here are some maintenance requirements for a macerating pump in a marine environment based on the search results123:

- The macerator pump should not be run without liquid going through it, as running dry can damage the impeller and the pump itself.

- The macerator control should be designed to “jog” the impeller once a week when power is on to prevent the impeller from taking shape and to help prevent it from running dry1.

- The macerator pump should be primed before use2.

- The macerator pump should be checked for clogs and blockages regularly3.

- The macerator pump should not handle hard objects, rags, or feminine napkins4.

It is also important to follow the manufacturer’s instructions for maintenance and operation of the macerating pump.

Bellows pumps are sometimes used instead of macerator pumps for marine applications. Here are some relevant information about bellows pumps1:

- Bellows pumps are non-macerating waste discharge pumps that use a flexible rubber bellows to pump out waste.

- They are simpler and less expensive than macerator pumps.

- They are less prone to clogging than macerator pumps.

- They are not as efficient as macerator pumps in breaking up solid waste and toilet paper, which can lead to blockages in the pump out station’s hoses and pipes.

Whether a bellows pump is better than a macerator pump depends on the specific needs and preferences of the boat owner. Bellows pumps require less maintenance than macerator pumps, but they are not as effective in breaking up solid waste. Ultimately, the choice between the two types of pumps depends on the boat owner’s priorities and budget.

No place on a vessel will be changed as much in the near future as the placement of instruments. We used four Garmen Chart Plotters on Sea Home. The most up to date was on the main deck. Another was on the fly bridge. A third was at the center console of the dinghy. And the fourth remained on our Macgregor 26x but we brought along the iPad companion to it. That iPad contained Active Captain Software from Garmen with the most up to date charts. We also used cell phones for tide and currents, AIS tracking, anchor alarm, and weather reports. The above has the potential to replace all of that plus Sea Home’s entertainment system.

Replacing sailboat diesel engines

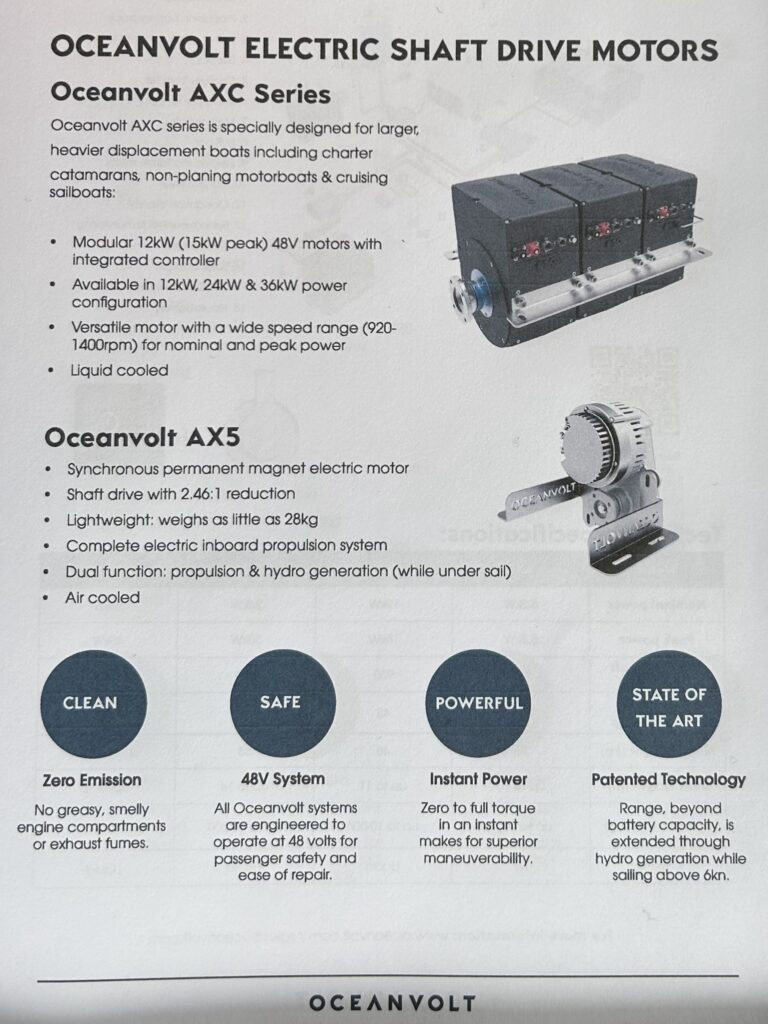

Boat manufacturers may not widely incorporate solar panels into their designs due to various reasons such as cost, space limitations, and the availability of alternative power sources like OCEANVOLT’s sail drive motor and hydrogenerator1. The Volvo Ocean Race tested hydrogenation, which allows the propeller to spin while sailing, and used a hydro-generator to supplement electric power needs1.

The use of generators to supplement electric power needs is also influenced by factors such as fuel efficiency, as seen in the real-world fuel consumption testing performed by Volvo Trucks5. The transition to new engine and fuel standards, including the use of high-efficiency exhaust emission controls, is also a significant consideration in the marine industry3.

Incorporating solar panels into boat designs may involve trade-offs and considerations related to the overall energy system, space, and cost, which could explain why manufacturers may rely on dealers and owners to add solar power. Sailboats have the possibility of bypassing solar for hydro generation.

In February of 2023, I investigated a Juneau sailboat engine replacement with an electric motor and hydro generation.

The Jeneau sailboat removed its small diesel and in its place installed lithium iron batteries and hydrogeneration. The original fuel tanks were not removed.

The vessel retains its Diesel generator and original fuel tank because they were already there. But the owner expects that Diesel generated power will not be needed because he prefers docking where electrical hookups are available. He intends to switch to renewable Diesel which is less expensive in Seattle than fossil based Diesel.

Lots of space unused after diesel was replaced with batteries and electric motor.

Oceanvolt AXC series is specially designed for larger, heavier displacement boats including charter catamarans, non-planing motorboats & cruising sailboats: Modular 12kW (15kW peak) 48V motors with integrated controller Available in 12kW, 24kW & 36kW power configuration Versatile motor with a wide speed range (920-1400rm) for nominal and peak power Liquid cooled

Oceanvolt ServoProp

The patented Oceanvolt ServoProp variable pitch sail drive combines a high efficiency sail drive with the most powerful hydro generator on the market. The unique feature of the ServoProp is the possibility to turn the propeller blades more than 180 degrees.

+30% increase in forward propulsion

ServoProp is capable of generating more than

1 kW at 7-8 knots

3 kW at 11-12 knots

The ServoProp is suitable as a propulsion motor for monohulls up to 50 ft & multihulls up to 60 ft. It can also be used as a hydro generator in boats up to 100 ft.

Light weight combination of a powerful sail drive motor and hydrogenerator. 48V synchronous permanent magnet motors with low drag & silent salldrive design.

The challenges of incorporating solar panels into sailboat designs include:

- Energy Storage: One of the primary challenges is energy storage. Innovative solutions, such as solar battery chargers, have emerged to address this issue1.

- Space Limitations: Unless it is a luxury yacht, space is likely to be at a premium, and finding the space to install solar panels can be a challenge4.

- Efficiency and Durability: The efficiency and durability of solar panels, particularly when exposed to marine environments, are important considerations5.

- Installation and Maintenance: The installation of solar panels on boats requires careful consideration of mounting, orientation, and maintenance to ensure optimal performance3.

- Power Discrepancies: There can be confusion about how much power can be harvested from a solar installation, and it’s important to manage power discrepancies effectively3.

In summary, the challenges of incorporating solar panels into sailboat designs include energy storage, space limitations, efficiency, durability, installation, maintenance, and managing power discrepancies. Despite these challenges, the benefits of solar power, such as clean and renewable energy, make it an attractive option for boat owners.

Possible replacements for solar panels on boats include glass panels, films, and wind generators. Glass panels and films are alternative forms of solar panels that can be used to harness solar energy. Wind generators, also known as wind turbines, can be used to generate electricity from the wind and are common on sailboats.

These alternatives can be considered based on factors such as energy efficiency, space availability, durability, and the specific needs of the boat. Each option has its own advantages and limitations, and the most suitable choice depends on the particular requirements of the vessel.

When selecting a vessel ideal for electric motors with the goal of maximizing distance traveled on a single charge, several factors must be considered:

Hull Type and Shape

- Waterline Length: Longer waterline lengths contribute to higher speeds. Aim for a hull that maximizes waterline length when under power1.

- Displacement: Lighter boats are faster for a given hull length. A moderate displacement-to-length ratio (around 150) is recommended for the best range in electric boats1.

- Wetted Surface: Minimize the wetted surface area to reduce drag. Round hull sections are preferable1.

- Transom Immersion: The transom should just touch the water under power to avoid creating drag1.

- Hull Section: Rounded sections minimize eddy resistance. Sharp corners should be avoided1.

- Bow and Stern Shape: A narrow bow (fine entry) and long, straight stern sections are ideal for minimizing resistance1.

- Windage: Minimize wind resistance by reducing exposed areas such as freeboard and awnings, especially in windy conditions1.

Keel

- Flat Keel: Common in ocean-going vessels, provides a solid foundation and is often used with a double bottom hull2.

- Bar Keel: Stronger and heavier, suitable for smaller vessels where grounding is a risk2.

- Duct Keel: Offers high strength and allows for protected cable and pipeline runs, used in double bottom hull ships2.

Propeller

- Efficiency: An efficient propeller design is crucial for electric propulsion systems. The design should consider the matching of all components for optimal efficiency4.

- Power and Speed: Electric motors are more efficient than combustion engines, and the power required depends on the hull type and intended use. For displacement boats, about 0.5 kW per ton of boat weight is sufficient for 70% of hull speed3.

Boat Length

- Longer Boats: Generally, longer boats are more efficient as they have higher theoretical maximum hull speeds1.

Other Considerations

- Weight (Displacement): A lighter boat requires less energy to move, which is beneficial for electric propulsion1.

- Appendages: Minimize the surface area of appendages like skegs and keels to reduce parasitic drag1.

- Power Consumption: Be mindful of the exponential increase in power consumption at speeds above 80% of the hull speed. It’s recommended to operate at an economic speed for longer driving time3.

In summary, the ideal vessel for electric propulsion aiming for distance on a single charge should be long and light, with a hull shape that minimizes resistance both in the water and against the wind. The keel should be appropriate for the vessel size and intended use, and the propeller must be efficiently designed to match the electric propulsion system. It’s also important to operate at an economic speed to maximize the distance traveled per charge1234.

The ideal propeller size for an electric boat is influenced by several factors, including the motor’s power output, the boat’s size and weight, and the desired performance characteristics (speed, efficiency, maneuverability). From the search results, a few key points emerge:

- Propeller Efficiency: A fixed three-blade propeller is recommended for the best overall motoring performance, balancing efficiency with sailing drag. However, the choice between two-blade, three-blade, and feathering or folding propellers depends on the specific trade-offs between motoring performance, sailing drag, and maneuverability3.

- Propeller Sizing: The most important factors in determining the ideal propeller size are diameter and pitch. These dimensions directly affect how much power the propeller can absorb at a given shaft speed. For electric propulsion, ensuring the propeller does not absorb too much or too little power is crucial to prevent overloading or overspeeding the motor34.

- Optimum Diameter: For electric drives, optimum propeller diameters might be up to 18” and 20”, but compromises may be necessary based on the available draft and hull clearance. Large diameter propellers are generally preferred for their efficiency, but the specific size should be determined based on the boat’s characteristics and performance requirements5.

- Material and Construction: Propellers can be made from various materials, including aluminum and stainless steel, each offering different benefits. The number of blades, along with design features like rake and cup, also plays a significant role in performance4.

- Manufacturer Recommendations and Testing: Starting with the manufacturer’s recommendation for propeller size is a good initial step. Testing the engine at Wide Open Throttle (WOT) and adjusting the propeller size based on the RPM achieved can help fine-tune the selection for optimal performance4.

In summary, the ideal propeller size for an electric boat depends on a careful balance of efficiency, power absorption, and the specific performance goals of the vessel. Consulting with professionals and conducting thorough testing are recommended steps to identify the best propeller for a given electric boat setup345.

Outboards more popular in new designs

Recent shifts toward gasoline outboard engines in boat design reflect a combination of cost, maintenance, and performance preferences, with freed-up space often repurposed for advanced systems like stabilizers or battery banks. Here’s a breakdown:

Why Gasoline Outboards Are Favored

- Lower Initial Cost:

- Ease of Maintenance:

- Noise and Space Efficiency:

- Performance for Smaller Boats:

How Freed-Up Space Is Utilized

- Seakeeper Stabilizers:

- Lithium Battery Banks:

Ventilation Requirements for Gasoline Outboards

- Mandatory Pre-Start Ventilation:

Trade-Offs

FactorOutboard GasolineInboard DieselFuel Efficiency~50% higher burn at cruise vs. diesel3Superior efficiency at cruise speeds2Resale Value~$10K lower1Higher retentionSafetyExternal fuel tanks reduce fume risks16Diesel’s lower flammability

Conclusion

The trend toward outboards reflects consumer prioritization of cost savings, simplicity, and modern amenities over diesel’s fuel efficiency. Freed space is increasingly allocated to stabilization and energy storage, while stringent ventilation protocols mitigate gasoline’s risks. For larger vessels or long-range cruising, diesel retains advantages, but outboards dominate the sub-32′ market23.

An innovation, I expect will find its way into Yacht Design, involves port lights. We replace the forward plexiglass windows (portlights) with new ones every 5 years or so as needed. They are important for visibility while operating our Macgregor 26X. The sun is constantly degrading them. How great if the sun could also generate electricity! The technology in the video is very intriguing. Enough energy could probably be produced from the forward port lights to keep the 12 volt thermal cooler running.

Grey Wolf, a cold-molded wooden 40 foot mono-hulled water-ballasted sailboat won the race to Alaska (R2K) in June of 2023. She flew the Seattle Yacht Club burgee at the Juneau AK finish line, taking the $10,000 first prize. She is the second SYC monohull in a row to do so but unlike Dark Star, the previous R2K winner, Grey Wolf did not go to the west side of Vancouver Island. No boat did that in 2023 owing to the 50 knot winds predicted there. The East inside-passage route past Vancouver Island saw 40 knot winds. Grey Wolf crew reported that all the prize money will go for replacement sails as the race inventory of sails had all been blown out. Bottom line, the hoped for future of yacht design involving new wooden hulls appears a trend. Grey Wolf has a unstated carbon fiber mast but the hull is wood molded into fiberglass.